The humble battery has emerged as a key technology to achieve a future powered by renewable energy. But can they be made sustainably?

In the latest episode of A Positive Climate, we learn about how an Australian startup is cleaning up lithium extraction to meet the growing demand for battery storage.

Why clean lithium matters

As we transition to renewable energy and electrify our homes, vehicles and industry, Australians stand to benefit more than most. We have a vast, windswept and sunbaked landmass, and world-leading rates of rooftop solar installations. But using that clean energy to meet our needs around the clock demands a lot of energy storage.

Fortunately, we also have the world’s fifth largest lithium reserves, with an estimated eight million tonnes underground and the world’s largest lithium mine already operating in Western Australia.

But is there a sustainable way to turn that resource into energy storage, or is lithium mining as inherently unsustainable and polluting as some might have you believe?

Steven Vassiloudis, the founder and CEO of Australian startup Novalith, says today’s processes can be made cleaner and cheaper without compromising on ethics, which will be important to meet growing demand.

"Last year we produced 130,000 tons of lithium globally…. by 2030 we need to produce three million tons of lithium. So that’s a twenty-three times increase in pretty much a decade,” he said.

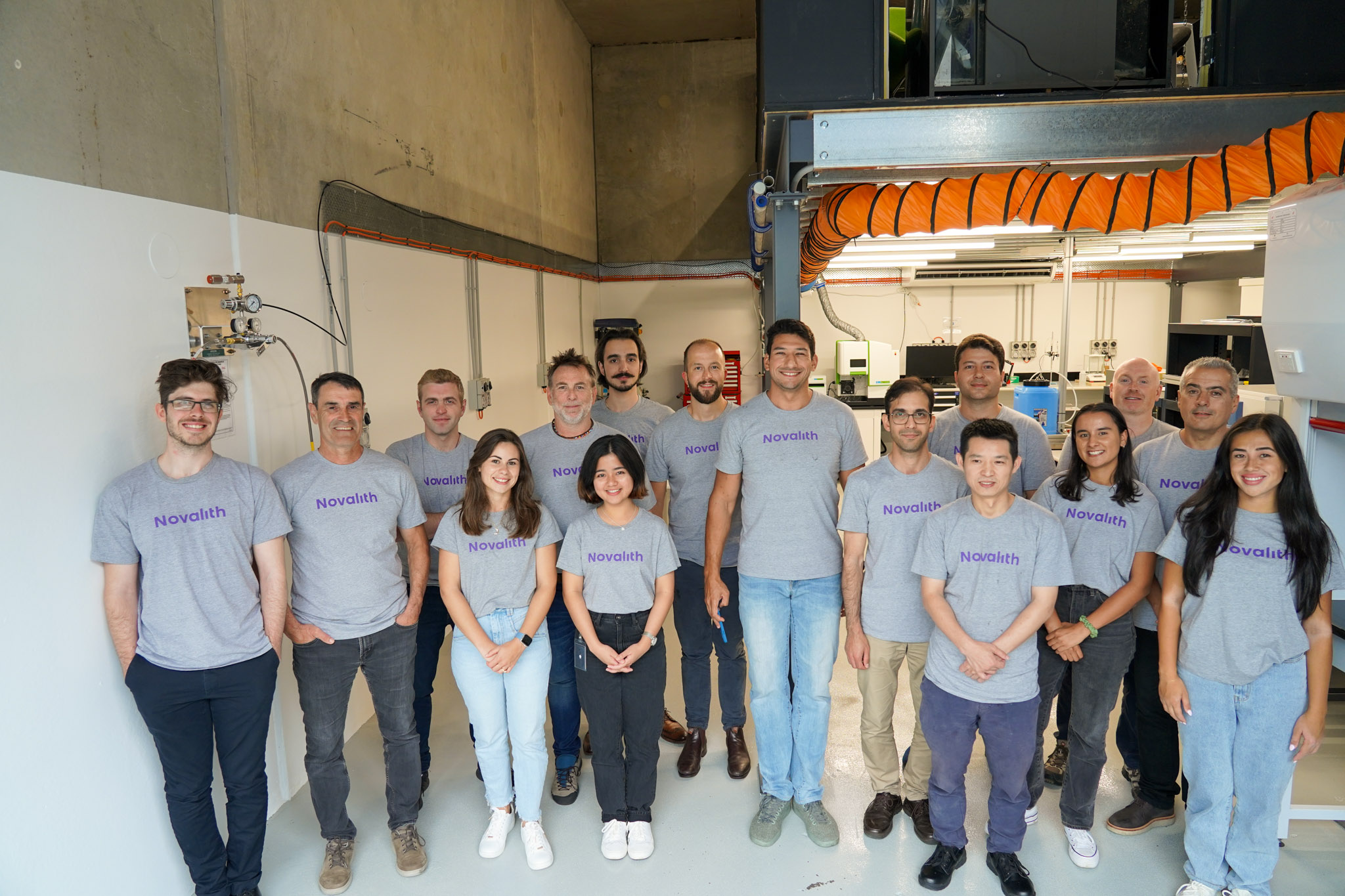

Together with a team that has grown to nearly 30, Novalith has set out to transform production methods, developing a new way to refine high grade lithium from even low quality ores.

Novalith founders Steven Vassiloudis and Christiaan Jordaan

Chance breakthrough

The technical breakthrough came by accident at the University of Sydney, where Dr. Brian Haynes and his team in the School of Chemical and Biomolecular Engineering were studying mineral carbonation and discovered that the process could effectively extract lithium.

“They were looking to do work on mineral carbonation, that's effectively just pumping CO2 and fixing it in rock. They found that chemistry, for whatever reason, did a really, really good job at extracting lithium from lithium bearing ores,” Steven said.

”And that was pretty much the origin story. So briefly after we spun it out, raised some money and here we are a couple of years later.”

Novalith applies the system using carbon dioxide recycled from industrial processes to replace common refining methods that rely on polluting acids and bases.

“So we effectively use CO2 plus water to produce carbonic acid, and we use the carbonic acid to strip lithium and extract lithium from your lithium-bearing ores to directly produce a lithium chemical, which is lithium carbonate.

“That allows us to extract the lithium very effectively and overcome a lot of the issues with the conventional processes,” Steve explains.

He says the technology offers a way to reduce emissions across the supply chain. Currently, most Australian lithium is dug up and shipped to China at between five and six per cent lithium oxide concentrations. From there it is converted into lithium hydroxide or lithium carbonate for use in the batteries we rely on to power everything from phones to cars and the electricity grid.

The efficiency of Novalith’s approach means the lithium requires less processing, which helps to reduce the cost of production.

Steven told us their system produces less than half the emissions of conventional refining methods across the supply chain, while reducing operating expenditure by more than 65 per cent and cutting capital costs by more than 50 per cent.

Scaling up production

Novalith’s mid-2021 seed round was led by backing from the Clean Energy Finance Corporation, with the funds used to confirm the science and economics of Sydney University’s discovery would stack up. The original founding team was Steven, Christiaan Jordaan (the co-founder of battery technology company Sicona, who just also raised a $20 million+ round and appeared on the podcast in 2021!) and Andrew Harris.

Team Novalith

A Series A in late 2022 raised $23 million including investments from Lower Carbon Capital, CEFC/Virescent Ventures, TDK Ventures, Grantham Foundations Neglected Climate Opportunities Fund and Investible.

The company is using the funds to establish a pilot facility to scale up production from the early laboratory tests to produce tens or hundreds of kilograms of lithium. Once proven at that volume, they are aiming to step up to a commercial scale facility within the next couple of years.

While they aren’t ready to announce any commercial partners, Steve says that Novalith is in discussions with everybody from mining companies to resource owners and electric vehicle manufacturers.

“At the end of the day, people say that they really do care about the environment and green credentials. But if it's more expensive and appreciably more expensive, people will go for what's cheapest and easiest,” he said.

“As much as we'd like to say that we won't mean the vast majority of people will opt for, for cost, we are very, very cost competitive.”

Novalith sees big opportunities for Australia if more lithium processing is undertaken onshore.

“We could become one of the lithium powerhouses globally, producing lithium chemicals onshore cost effectively. Given the nature of our process… we have a huge opportunity in Australia, as well as in Europe and the US and I mean, we're the luckiest of the bunch.”

Join the conversation

Thanks to you all for being part of A Positive Climate and sharing your ideas and questions. If you want to ask Nick or Alex a question or share your thoughts, email hello@apositiveclimate.com or hit us up on LinkedIn or Instagram.

Stay on the pulse of climate innovation and subscribe to our newsletter. There will be a bit about the podcast, but also other news about the latest tech and innovation you will love.

Don’t forget to hit FOLLOW in your podcast app and look out for us in your feed with another episode every fortnight on Tuesday mornings.

- Nick and Alex